|

|

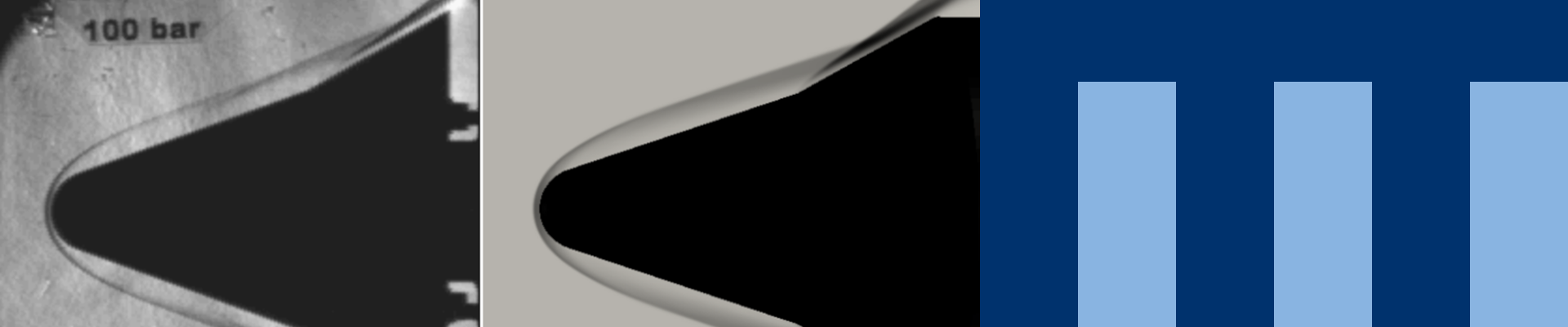

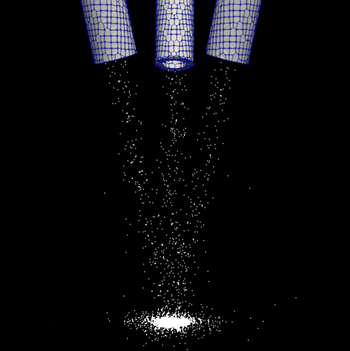

Polydisperse particle-laden jet flows at high Stokes numberParticle-laden turbulent flows are extremely complex due to the intrinsic chaotic nature of the carrier-phase turbulence and the random character of the dispersed-phase distribution. In many applications, however, additional complexity often arises from interactions of such flows with other complex phenomena, such as evaporation, melting, and chemical reactions. Although a profound insight into many features of particle-laden turbulent flows has been gained from previous laboratory and numerical studies, characterization of such flows still remains elusive. This lack of characterization is partly because of the aforementioned, intrinsic complexity of the system and partly because of a large number of controlling parameters, namely, Reynolds number, Froude number, particle Stokes number, and mass loading. |

|

|||

|

|

|

||||

|

|

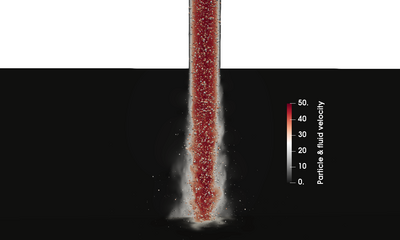

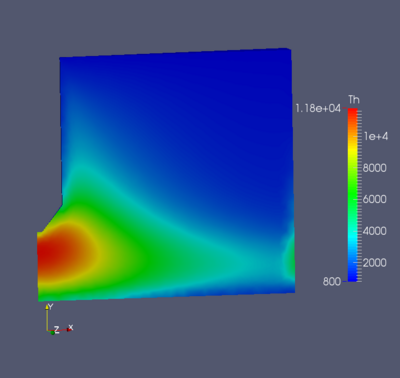

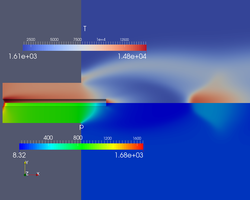

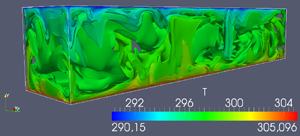

Heat conduction and ventilation in a moon habitat laboratory module

Human spaceflight demands systems that provide a livable environment for humans i.e. in habitats for long duration missions on other planets. This challenge involves the design of several subsystems

of the life support system according to comfort criteria, including air management and ventilation of supply air. To ensure a comfortable room climate with fresh air while being able

to remove waste heat of the habitat's systems are main goals of the ventilation system. |

|

|||

|

|

|

||||

|

|

AulaPRO: Adaptive Powder Feed for Additive Manufacturing Processes

Due to the extensive developments in the past decades, numerous different system technologies for powder feed or powder nozzles for laser powder build-up welding

have established themselves on the market. In general, the powder feed systems are divided into lateral and coaxial systems. In the case of lateral nozzles, the powder

is supplied from a powder nozzle and only from one direction, so-called off-axis nozzles. The process is therefore direction-dependent. The nozzle shape can be designed

as a round tube or in the form of a wide slot nozzle. Lateral powder feed systems are a widespread, established technology for powder feed when coating and repairing

geometrically simple components such as rollers, shafts, etc. using LMD. |

|

|||

|

|

|

||||

|

|

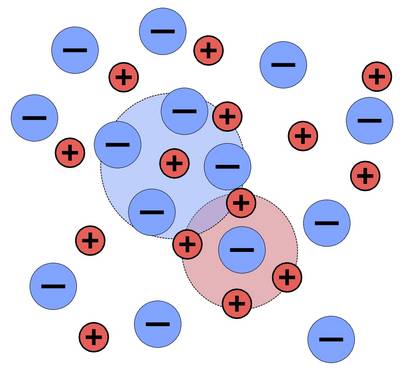

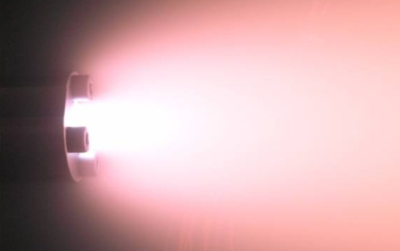

Modelling electric Discharges/Arc with PIC methods

The research on thermal electric arcjet thrusters has been the subject of several projects of the Thermofluid Dynamics division at ZARM ranging from experimental investigation to the numeric modeling.

One challenging aspect in the modeling of these type of thrusters always has been the description of the arc, which is responsible for the heating of the propellant through the process of Joule heating.

Fundamentally, electrons originating from the high current arc burning in the partly ionized propellant, collide with atoms and thereby increasing the thermal energy of the neutral species. |

|

|||

|

|

|

||||

|

|

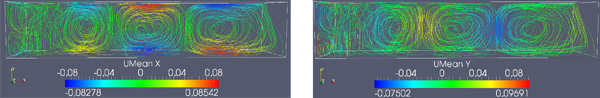

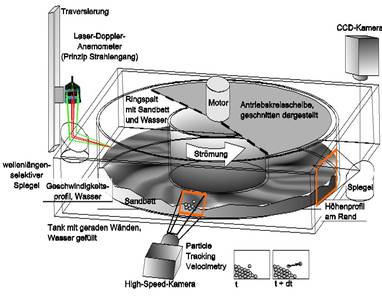

Grindball: Hydraulic Driven Grinding ToolThis project is a cooperation work together with the laboratory for micro cutting (LFM) and institute for electric drives (IALB) at the University of Bremen. Central idea of the projects is the development of a microscopic axis-less grinding tool. The central element of the grinding tool is a microscopic ball, which is driven by hydraulic forces of a surrounding liquid bed. Additionally the ferromagnetic ball position is controlled by an electromagnetic field. Because of the high liquid mass flux, needed by the hydraulic driving system, the Reynolds number of the flow inside the sphere gap is increasing over the critical Reynolds number of transient turbulent flow. Therefore the hydraulic shear forces depend on the thickness of the turbulent shear layer at the ball surface. Primary topic of this research project is the fluid/structure interaction of transient turbulent shear flows in an electromagnetic controlled positioning system. Changing the position of the grinding ball the flow character of the surrounding liquid flow changes depending on the minimum gap size between the ball and its bed. |

|

|||

|

|

|

||||

|

|

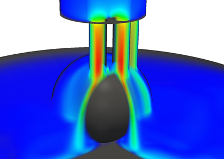

Thermo-Electric Emission for Plasma Processes

Just as in an arc welder, a high-current electric arc is struck between the anode and cathode. As the cathode heats up, it emits electrons, which collide with and ionize a propellant gas

to create plasma in MPD thruster. For gases, there are many circumstances where the electron temperature T_e differs from the heavy particle ( ions and neutral atoms) temperature T_h.

The electrical conductivity and other coefficients in the equations of motion depend on T_e. It's therefore necessary in such circumstances to include T_e among the variables which define

the state of gas, and to employ an additional equation which governs the behavior of the electron temperature. |

|

|||

|

|

|

||||

|

|

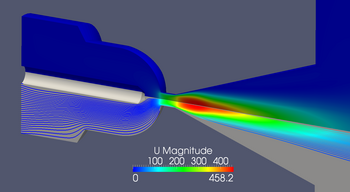

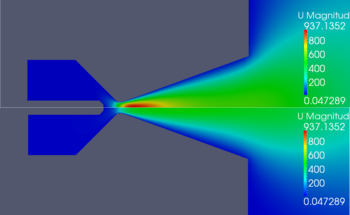

Computational Arc-Jet ModellingTotal fuel mass is one of the main economical and technical restrictions while designing space propulsion systems. Given the high costs related to the transport of mass into space, the total fuel mass necessary for accomplishment of the mission should be minimized. An optimum thrust/fuel consumption ratio demands the maximization of the gas exit velocity for a given mass flow. This can be achieved through the increase of propellant temperature and pressure in the propulsion system, which results in higher values for the speed of sound at the throat of the de Laval nozzle. |

|

|||

|

|

|

||||

|

|

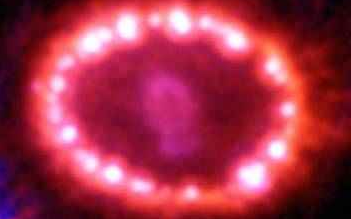

Modelling Astrophysical Hydrodynamics

One of the most amazing applications of magneto fluid dynamics are astrophysical approximations. High temperatures are responsible for fusion and ionization processes in space.

Furthermore, the motion of charged particles in space is part of its astrophysical description. The motion of charged particles near planets with a magnetic core or inside accretion discs

in the environment of a black hole is the result from attaching forces of other particles and is influenced by electric and magnetic fields. |

|

|||

|

|

|

||||

|

|

Ionization and Thermo-electric Thruster SystemsWhen the difference in electric potential between electrodes with different charge is high enough, an electric discharge through the fluid medium separating the electrodes occurs. The resulting electric flux is associated with a local motion of electrons, the only mobile charge carrier inside the solid electrodes. As a result from the motion of electrons and the collisions and resistance forces inside the conducting electrodes, a local temperature increase occurs. The resistance against electron motion in fluid media is a result from similar forces. The biggest difference lies in the mobility of the charge carrier phase molecules. As in the solid electrodes, the electric conduction through a fluid phase leads to a local heating. Furthermore, higher temperature values increase the mean free path of the particles and reduces the electric resistance of the fluid. This region is characterized by the appearance of an electric arc. |

|

|||

|

|

|

||||

|

|

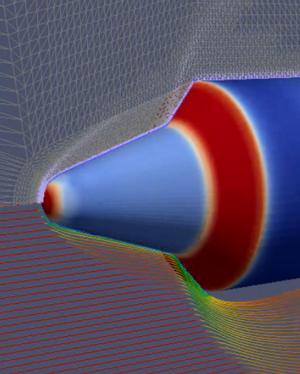

Computational Modelling of Shock Waves in Transsonic Flow Regime

When developing machines and facilities with optimization regarding fluid dynamic behavior, the form of the optimization tools results from the operating conditions of the studied flow

(laminar, turbulent, incompressible, trans-sonic, hyper-sonic, molecular, continuous etc.). If mixed conditions are present, the interactions between the sub-models has to be investigated

and modeled through coupled transport equations. |

|

|||

|

|

|

||||

|

|

Heat Transfer and Convective FlowsThe computational description of evaporation processes requires the calculation of the heat and mass transfer exchange rate over the liquid/gas interface. The most influential parameter for the exchange rates is the relative humidity of the gas phase. The highest relative humidity gradient occurs at temperature levels slightly below the boiling point. As a result, these temperatures have to be considered when computing the dispersed phase evaporation driven by temperature increase. |

|

|||

|

|

|

||||

|

|

Ion Flow

An electric propulsion system has been assembled on the ZARM institute. This propulsion system is actuated with an electrical power up to 500W and inert gases as propellants.

During the experiments the pressure inside the test chamber is between 0.1 and 1 Pa. Still at the moment the runtime is limited to only a few seconds, because of the electric heating. |

|

|||

|

|

|

||||

|

|

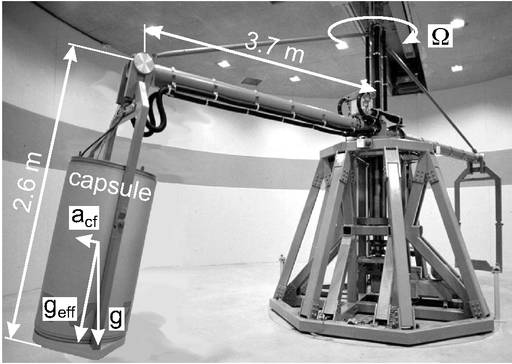

Turbotherm

Hurricanes are effected by turbulent natural convection flows, which are caused by solar radiation. To understand the hydrodynamic stability of these flows, especially in terms

of the Coriolis acceleration of the earth rotation, the first step is an investigation of a simplified convection problem. Therefore, a suitable experimental setup is compared

with numerical simulations. Convective flows in the atmosphere are drive by cold air streams over warmer layers on heated ground.

The forced convection moves heated air in higher regionsof the atmosphere. |

|

|||

|

|

|

||||

|

|

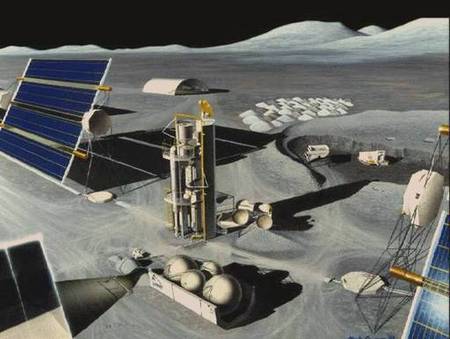

Autarc Lunar Infrastructures

It is proposed to establish a Collaborative Research Centre (SFB) with the title Autonomous Lunar Infrastructures (ALI) at University of Bremen with several cooperating partners close by.

Bremen is an important site in Germany where space related activities are concentrated with more than 1500 engineers and scientists working in the fields of development, production,

operation and utilisation of orbital and exploration systems, satellites and launchers. |

|

|||

|

Excluded from the considerations are: Within the scope of the planned work key technologies will be developed in each of the project groups up to the level of prototypes (breadboard or down-scaled demonstration hardware) which will be tested in cooperation with AWI in later funding periods under demanding conditions in the Antarctic. Besides the low temperatures and the increased UV radiation due to ozone depletion in the southern hemisphere, the Antarctic winter over nearly half a year without sunlight (partly with temperatures as low as -90°C) serves as an unrivalled challenge for every prototype, which can hardly be found at other places on the earth. |

|

||||

|

|

Convectice CoolingThermally driven flows are described as a turbulent compressible Rayleigh-B´enard problem. For the numerical discretization of the Large-Eddy-Simulation the flow is separated in large and small scales, the so-called sub-grid scales. The large scales are solved directly on the discretisation grid, while the sub-grid scales are modelled with an applicable turbulence model. |

|

|||

|

|

|

||||

|

|

Debris Flow

This set-up forces a debris flow at the ground of the cylinder. Additionally the interface between debris and liquid media is destabilized. The new steady shifting form depends on debris

material and the mean shear stress at the surface of the granular bed. Inside the debris flow cylinder a steady shear flow controlled by a rotating disk is built up. The shear stress

inside the layer between forcing upper wall and the granular bed induces interaction forces between the moved fluid and the solid particles at the ground. |

|

|||

|

|

|

||||

|

|

Double Cone

The subject of interest is the validation of a 3-D numerical computer model of a hypersonic flow around double cone geometry. The double cone geometry represent a generic space vehicle

which enters an atmosphere with very high velocity. This leads to a complex flow phenomena around the space vehicle. In this poster results of the investigation are presented. |

|

|||

|

|

|

||||

|

|

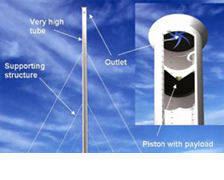

Space Blast Pipe

The objective of this study is to prove the feasibility of the suggested technical concept and validate the elementary performance calculations. Besides gas- and thermodynamic analyses,

this includes basic examinations on some options for the supporting structure; the piston and the outlet mechanisms as well as the constructional constraints of the tube itself.

The unsteady flow and the time-dependent pressure distribution inside the blast pipe will be modelled, computed and simulated. This is necessary to predict the required power and to define

the different phases of the blasting process. |

|

|||

|

|

|

||||